Cutting-Edge

Contract Manufacturing Solutions

Not Your Legacy Aerospace and Munitions Manufacturer

Your Next-Generation Precision Machine Shop

Here at Liberty Precision, we have made strides to revolutionize precision machining for defense, aerospace, munitions, and other demanding industries. Our high-quality solutions allow us to provide complexity at volume, offering superlative quality at compelling price points.

Liberty Precision is not your legacy aerospace and munitions manufacturer. What exactly do we mean by this?

We like to think differently.

Liberty Precision is not like other shops, and we are proud to approach manufacturing with a unique mindset.

We employ creative contract manufacturing approaches to improve accuracy, shorten lead teams, and reduce overhead costs. Our out-of-the-box methodology has allowed us to improve our internal processes and drive results for our customers.

We offer solutions, not just services.

It’s one thing to simply get your parts made. It’s another to work strategically, using our cutting-edge equipment and our teams’ industry-specific expertise to provide the best possible outcomes.

We know how much we’re capable of, and we approach our customers’ needs with agility and high-level thinking. That’s what makes Liberty Precision a sought-after partner in complex machining.

We embrace modernity.

Many machine shops are stuck in their ways, operating the same way they have been for years and using antiquated technologies. This stuck-in-the-past mindset results in tedious manual processes and long lead times. We understand how shops can find themselves in this ongoing cycle – if something has worked in the past, it’s bound to be the right solution, right?

The team at Liberty Precision rejects this mentality, always thinking about the future of machining rather than reflecting on processes of the past. We continuously make investments in the most efficient software and technologies to improve and streamline our operations. We evaluate our own processes to enhance quality management and risk assessment, not just so we can meet AS9100 certified machining requirements, but so we can constantly evolve as an organization.

Complex Machining Solutions

Liberty Precision shines in the complex machining of parts in demanding industries, including:

Munitions

Aerospace

Medical

Defense

Space

Material Complexity

We have experience utilizing metals that are notedly difficult to work with, including (but not limited to):

Titanium

Inconel

Monel

316 and 304 stainless steel

Equipment Made for Complex Machining

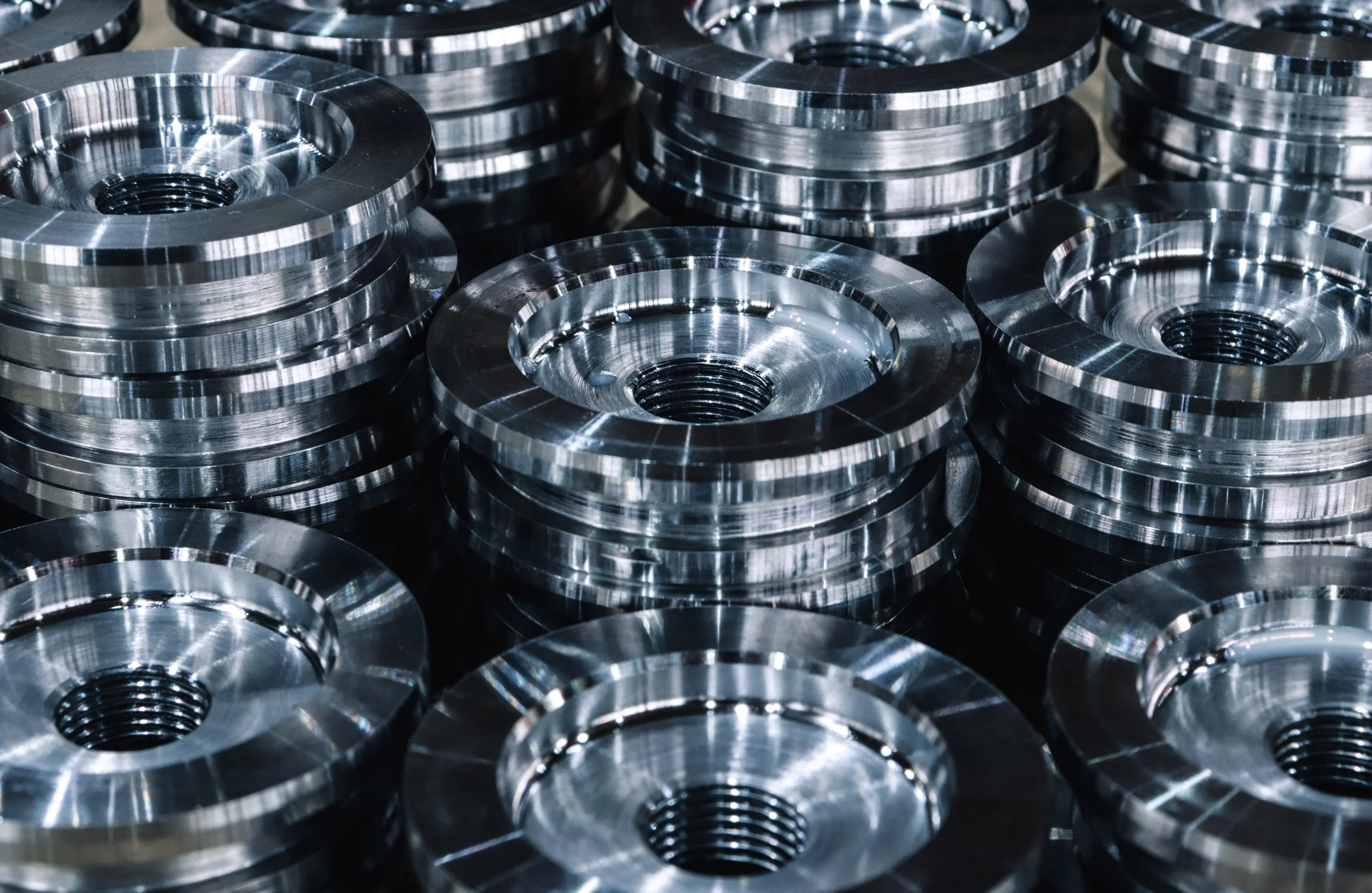

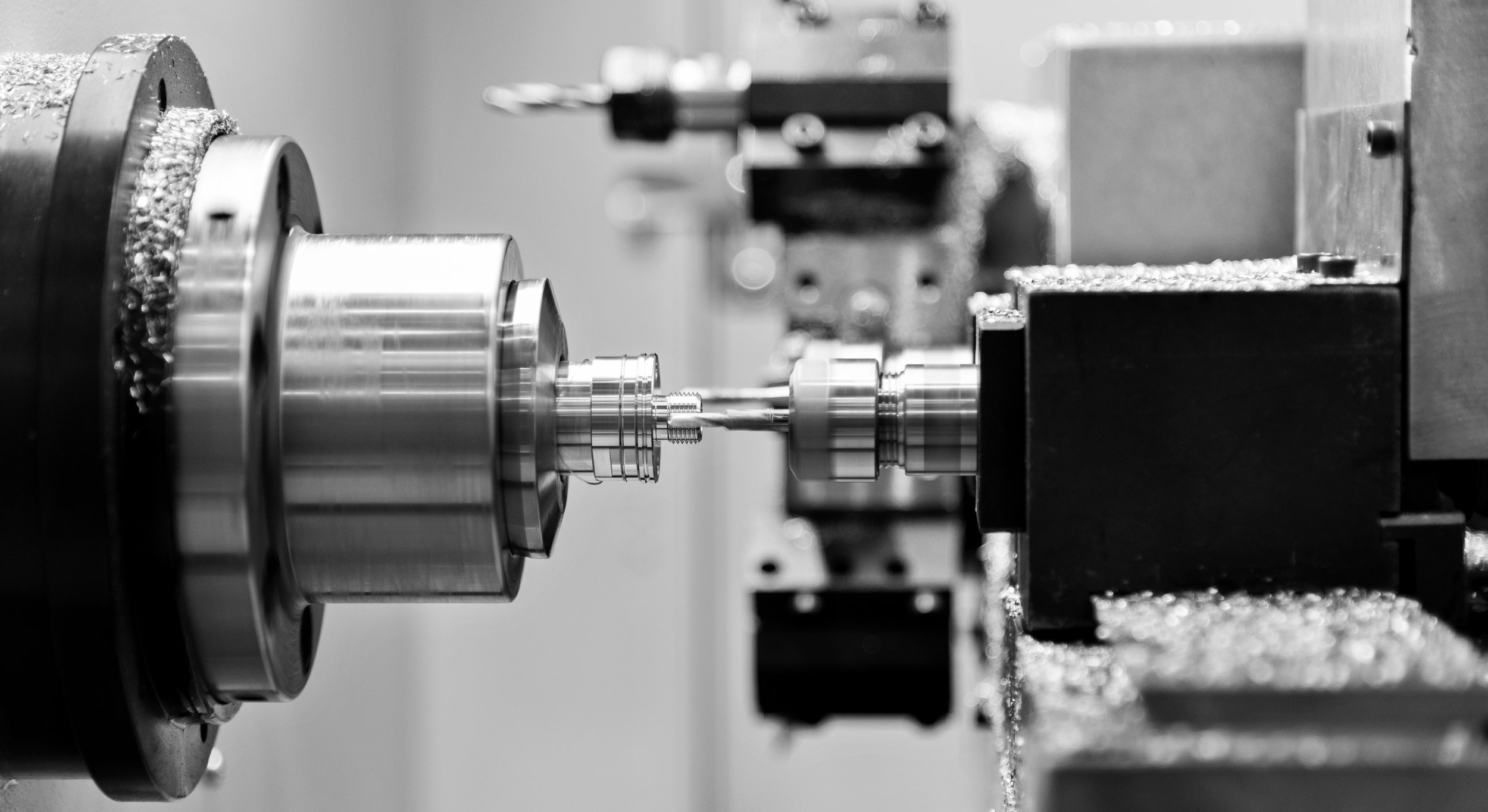

Liberty Precision invests in high-end equipment with complex machining capabilities in mind. The machines that make up our shop floor allow us to complete complex parts in a single setup. A greater number of axis leads to fewer machine setups, resulting in superior precision. This is especially crucial when machining complex components with tight tolerances and intricate geometries.

Complexity at Volume

Our equipment and strategic processes enable us to provide complex machined components at medium volumes, ranging from 1,000 to 100,000 pieces. The processes we employ in-house are highly repeatable, ensuring accuracy from one part to the next.

Agile Approaches at Liberty Precision

In addition to our complex machining capabilities, Liberty Precision approaches our precision machining services with agility. We’ve developed a process that allows for impressive speed without compromising quality to meet the needs of the demanding industries we serve. In the defense and munitions space especially, OEMs may need parts to provide our military with the tools and weaponry they need in a hurry.

Quick-to-Quote

Liberty Precision offers quick-to-quote solutions to ensure a seamless, efficient experience for our customers. Our advanced Paperless Parts quoting software allows us to evaluate project specs, materials, and complexities with speed to provide accurate quotes as soon as possible. Our quick-to-quote system not only saves valuable time, but also expedites the decision-making process for our customers.

Integrated Data Flow

We’ve seamlessly connected each stage of production to accelerate our in-house processes while ensuring the secure, accurate transfer of data. Our interconnected approach allows data to flow across multiple platforms, from our ESPRIT CAM software to our High QA quality management system and quality analysis documentation, and everywhere in between.

The integrated flow of data across our platforms produces the following results:

Streamlined in-house operations

Reduced lead times for our customers

Enhanced quality and precision

Single Operation

Liberty Precision has invested in technology that lets us fabricate complex parts in a single operation. This means we do not need to batch process parts through multiple machines, cutting down on production times and the need for manual intervention.

Best-in-Class Software

We use industry-leading software in many of our functions, such as the quoting process, model-to-machine capabilities, quality management, and inspection.

Here is the robust suite of software we use regularly:

Highly Skilled Engineers and Machinists

Our teams are highly trained, thanks in part to our employee upskilling program. Whether they are running our Swiss machining services or overseeing part inspection, our people are capable of leveraging our equipment and technology to produce the best possible outcomes for our customers.