Plastic Machining vs. Injection Molding: Making the Right Choice

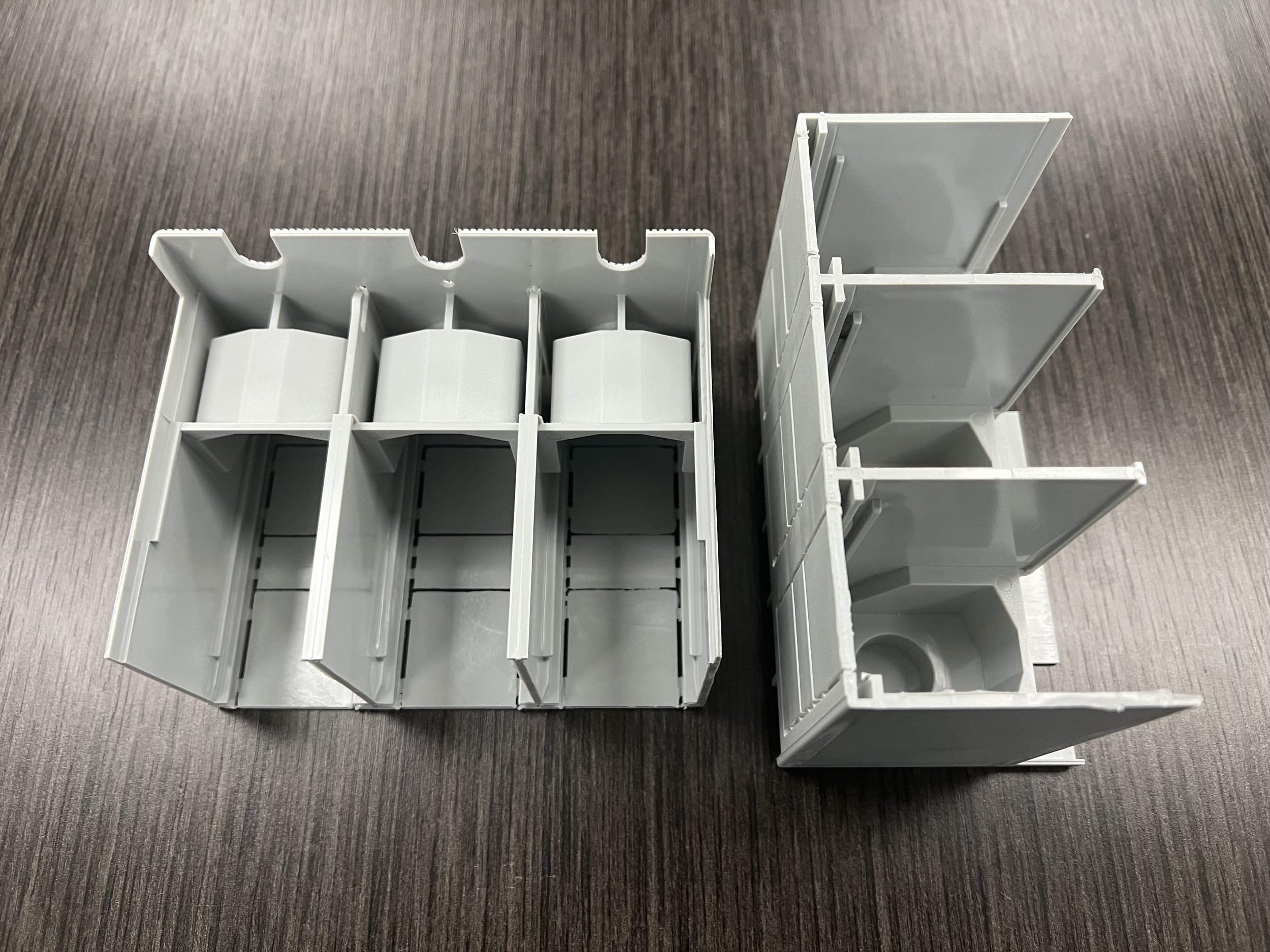

When producing plastic components, manufacturers often face a critical decision: should they use plastic machining or injection molding? While injection molding is a popular method, plastic machining is sometimes the superior choice—especially when precision, lower production volumes, or complex features are required.

At Liberty Precision, we specialize in high-quality plastic machining, offering solutions for industrial applications, medical devices, and aerospace manufacturing. Our expertise in CNC machining services allows us to deliver high-precision plastic components that meet exacting standards.

Why Choose Plastic Machining Over Injection Molding?

Two primary factors determine whether plastic machining is the right approach: tolerancing and production volume.

Tight Tolerances

Many precision machine shops struggle to maintain tight tolerances over large production runs when using injection molding. If a part requires tolerances tighter than ±0.002", machining is often the better manufacturing method. This is especially critical in applications requiring complex and high-precision finishes.

Low-to-Mid Volume Production

Injection molding is most cost-effective for very high production runs, typically 50,000 parts or more. However, when manufacturing smaller quantities, the upfront cost of molds may not be cost-effective. Machining offers a more practical and economical solution for these lower-volume requirements.

The Benefits of Plastic Machining

Beyond tolerance and volume considerations, plastic machining provides several additional advantages:

Efficient Single-Operation Production

Plastic machining allows for the production of complex machined components in a single setup, reducing the need for secondary operations such as deburring. This improves efficiency and ensures consistent quality across all parts.

Material Versatility

Machining processes are compatible with a wide range of engineering plastics, including glass-filled nylon and other specialty materials. This flexibility enables manufacturers to select the best material for their specific application without the constraints of injection molding.

Precision Features & Finishes

Certain design elements—such as milled flats, drilled holes, and high-precision surface finishes—are difficult or impossible to achieve with injection molding alone. Plastic machining provides the ability to incorporate these features directly into the production process.

When Is Injection Molding the Better Choice?

While plastic machining is the best option in many scenarios, injection molding is ideal when:

Mass production of 50,000+ parts is required

Lower per-unit costs are necessary at extremely high volumes

The part geometry is relatively simple and does not require additional machining

However, it's important to consider the high upfront costs of injection molding. Molds can be expensive, often costing tens of thousands of dollars, making them impractical for small or medium production runs. For companies that need flexibility, plastic machining remains the best solution.

Overcoming Plastic Machining Challenges

Machining plastics comes with its own set of challenges, but at Liberty Precision, we have the expertise and technology to address them effectively. Our AS9100D-certified machine shop ensures that every part meets strict quality standards.

Controlling Material Sensitivity

Plastics expand and contract with temperature changes, which can impact dimensional accuracy. Our temperature-controlled environment minimizes these effects, ensuring consistent quality.

Advanced Tooling for Plastics

Machining plastics requires specialized tooling to prevent heat buildup and material deformation. Our extensive knowledge enables us to select the best cutting tools for each material type.

Optimized Chip Control

Unlike metals, plastics do not break into clean chips, which can lead to melting and material waste. Through expert programming and cutting techniques, we maintain precision while preventing chip accumulation.

Why Choose Liberty Precision for Plastic Machining?

At Liberty Precision, we help customers determine the best manufacturing method for their plastic components. When machining is the right choice, our state-of-the-art equipment and skilled engineers ensure high-quality, precision machined components with fast turnaround times.

If you're evaluating plastic machining versus injection molding for your next project, let our team help. Contact Liberty today to discuss your requirements or request a quote to get started!